3d printer resin biocompatibility

It brings in high abrasion resistance and permanently smooth surfaces with easy anatomical shaping. Rigid biocompatible photo-sensitive 3D resins.

Zortrax Top Cover With Hepa Filter For M300 M300 Plus 3d Printers Hepa Filter Hepa Printer Cover

2009 to address cytotoxicity genotoxicity and delayed hypersensitivity and USP plastic class VI which includes the test for irritation acute systemic toxicity and implantation.

. Option The manufacturer offers a selection of resins to match machinemethod - Digital Light Processing DLP Digital Light Synthesis DLS Liquid Crystal Display LCD Stereolitography SLA Multi-Jet Printing MJP. A list of the recommended FDM materials is shown below. P3 Biocompatible Materials Loctite MED412 A tough durable resin designed with medical applications in mind.

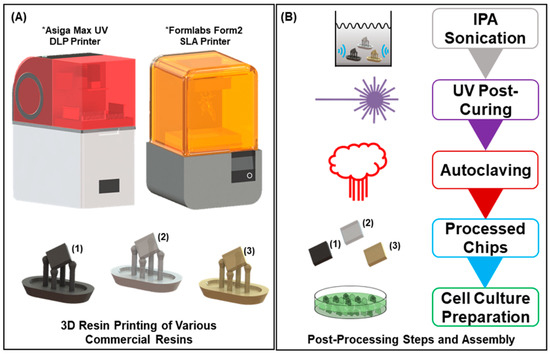

3D printing allows for the accurate and rapid design and fabrication of monolithic devices. 3D printer-compatible biocompatible resins polymers that have no skin reactivity carcinogenicity or reproductive toxicity. Cytotoxicity testing LDH test proliferation testing WST1 test and mechanical testing were also performed.

The first resin is the Raydent Crown Bridge class IIa biocompatible. Though 3D printing has been developing rapidly microfluidic developers avoid the adoption of 3D printing due to certain barriers on the resolution throughput and resin biocompatibility. 3Dresyns is the first and unique 3D resin supplier developing ultra safe functional monomer free and monomer based biocompatible 3D resins with non toxic risk pictograms.

Analysis of 3D printer resin for biological applications. This medical-grade resin is ISO 10993-5 and ISO10993-10 certified for biocompatibility and features an incredible elongation at break while lending itself to be easily machinable with a great surface finish following post-cure. The advantages of 3D printing resins.

We attempted to use these resins to produce direct aligners. Ideally you want to use FDM Fused Deposition Modeling materials used on professional 3D printers such as ULTEM 1010 resin with a Stratasys 3D printer. Flexible biocompatible photo-sensitive resins.

Naturally it is safe for contact with human tissue for this time period. The compatibility of the material to build microfluidic devices was evaluated in three different ways. FDM parts are strong reliable and can be sterilized with an approved process such as steam autoclave.

I determining if the ultraviolet uv cured resin. By introducing an in-depth post-printing treatment of these resins their biocompatibility can be dramatically improved up. Due to the increasing interest of manufacturers and companies in 3D printing resins and 3D printers are becoming more and more accessible to.

The widespread adaptation of 3D printing in the microfluidic bioelectronic and Bio-MEMS communities has been stifled by the lack of investigation into the biocompatibility of commercially available printer resins. Perfect smoothness of finished models The highest detail and accuracy Excellent physical and mechanical properties Wide range of materials and color palette The possibility of processing There are materials that can be used to make burn-out and lost-wax models. USP Class VI and ISO 10993-1 Information Biocompatibility Information for Materials A number of our plastic materials are ISO-10993 or USP Class VI capable.

The choice of ingredients must be considered as the toxicity varies depending on the photoinitiator and unreacted photoinitiator may leach out of the polymerized resin. To be classified as a bio-compatible materials 3D printed resins will undergo biologic evaluation according to ISO 10993-1. A selection of Figure 4 VisiJet Accura and DuraForm plastic materials have met the requirements of ISO 10993-5 -10 or USP Class VI testing.

As the name suggests it has dental applications but only temporary ones lasting up to 30 days. The resins tested for biocompatibility were Clear Resin FLGPCL04. Although this technology has revolutionized MEMS and microfluidics fields to our knowledge little investigation into the biocompatibility of the most commonly used commercial 3D printing resins has been performed to date.

Biocompatibility is important for the 3D printing of resins used in medical devices and can be affected by photoinitiators one of the key additives used in the 3D printing process. Our Biotough grades are ultra tough reaching 110-130 MPa in flexural strength and consequently are ideal for printing functional engineering and biomedical materials. The biocompatibility of photopolymers in additive manufacturing AM often referred to as 3D printing 3DP is an issue of concern due to among other things the unique parameters of the.

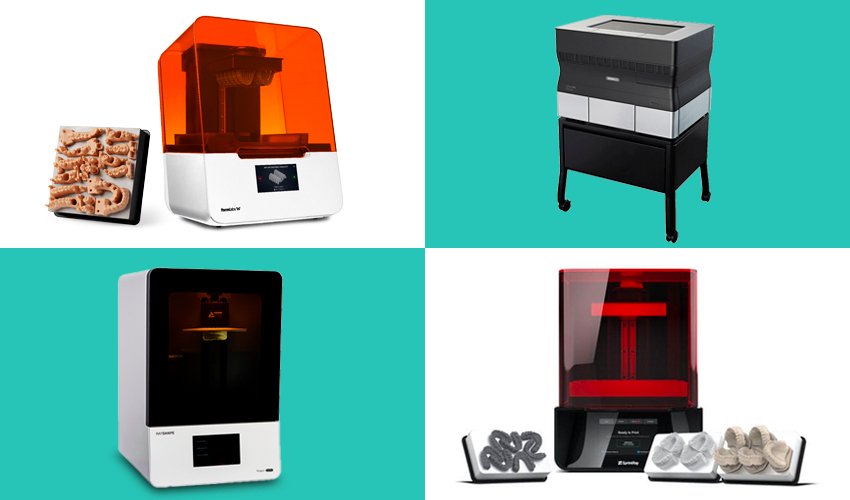

The appearance of low-cost 3D printers certified for the use of dental resins is turning it into an option within everyones reach. 3D printers have many merits such as they are inexpensive less time-consuming and are automated. Unlike photolithography they also have demerits.

This study aims to investigate the biocompatibility and physical properties of one such 3D printer resin NextDent Base Vertex Soesterberg The Netherlands and compare it to pre-existing conventional polymethyl methacrylate PMMA denture base Lucitone 199 Dentsply Sirona York Pennsylvania and milled PMMA denture.

How Biocompatible 3d Printing Is Changing Healthcare Med Tech Innovation

New Biocompatible Peek 3d Printer Filament Fabbaloo

Made To Order 3dresyns For Most Sla Dlp Lcd Inkjet 3d Printers

Zortrax M300 Dual Professional Large Volume Dual Extrusion 3d Printer Impression 3d Imprimante 3d Organisme De Formation

3d Printed Medical Models State Of The Art 2022 All3dp Pro

Biocompatible 3d Printing Materials For Implants Skin Contact Ask An Additive Expert Youtube

Etec Envisionone Desktop Dlp 3d Printer Continuous 3d Printing

The Dental Resin 3d Printers Currently On The Market 3dnatives

3d Printing Company Carbon Introduces Biocompatible Silicone Based Mat Plasticstoday Com

Guide To 3d Printing Medical Devices

3d Printing Induced Fine Particle And Volatile Organic Compound Emission An Emerging Health Risk Environmental Science Technology Letters

Biosensors Free Full Text Biocompatibility Of Blank Post Processed And Coated 3d Printed Resin Structures With Electrogenic Cells Html

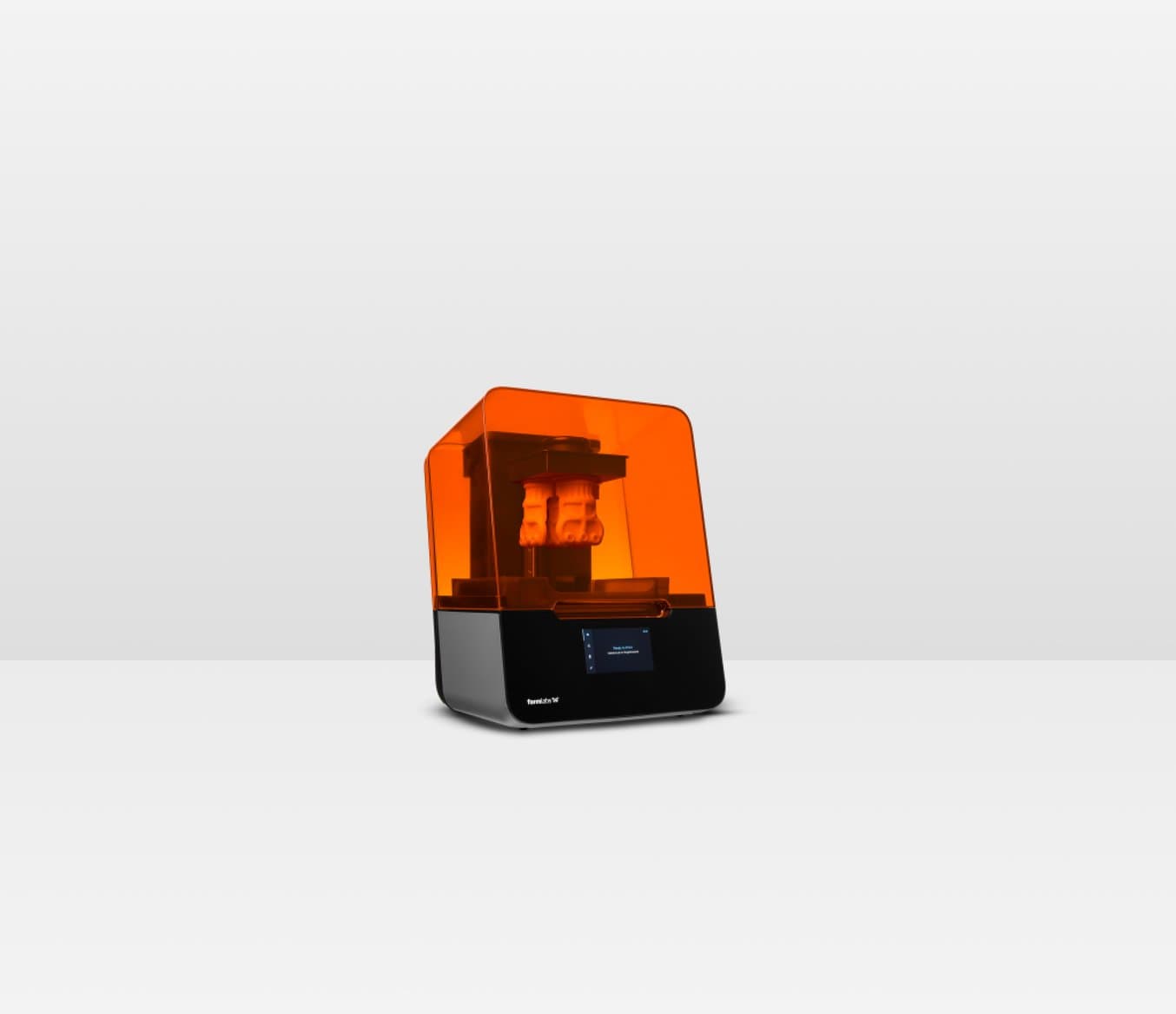

Form 3b The 3d Printer For The Medical And Dental Sectors

Applied Tutorial For The Design And Fabrication Of Biomicrofluidic Devices By Resin 3d Printing Biorxiv

Types And Applications Of Resins For 3d Printers

Stratasys Introduces Mid Size Biocompatible 3d Printer Fabbaloo

Rapidshape D50 Plus 3d Printer Fast And Automated Dental 3d Printing